In any fermentation or cultivated meat process, microbes are both partners and potential spoilers. The challenge is knowing which ones are present, how fast they are growing, and when they might cause trouble. Faster, clearer microbial insight matters because it helps producers protect product quality while scaling complex biological systems with confidence.

Turning Live Genetic Signals Into Operational Decisions

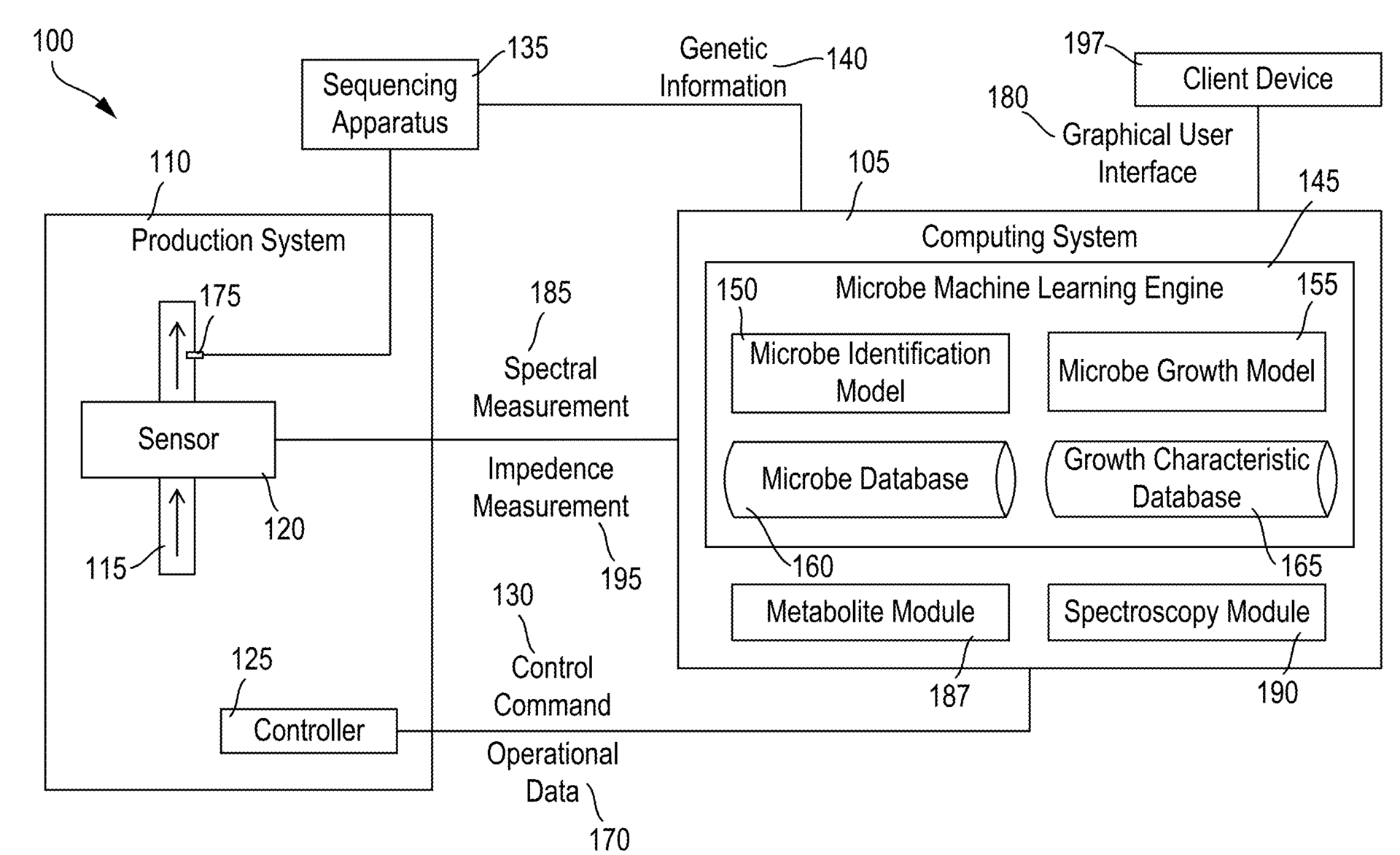

This patent describes a system for sensing and predicting microbial behavior inside a production line in near real time (WO2025244972A1). Instead of relying on slow culture tests, the setup pulls small samples from a pipe or tank and analyzes them using rapid genetic sequencing. The tool highlighted here is a nanopore device, which reads DNA or RNA by threading it through microscopic pores and producing results quickly enough to inform ongoing operations.

The genetic data feeds into machine learning models that identify which microbes are present and forecast how they will grow under the specific conditions of that line. The system also interprets clues from other inline signals, including impedance shifts between two electrodes and changes in transmitted light, which help detect live organisms and even early biofilm formation. Biofilms are the stuck-on microbial layers that cling to surfaces and are notoriously hard to remove, so spotting them early gives producers a meaningful advantage.

By pairing rapid sensing with predictive modeling, the invention supports data-driven cleaning schedules, targeted interventions, and more stable fermentation performance.

System overview for real-time microbial sensing and prediction inside a production line. (WO2025244972A1)

Laminar’s Push Toward Closed-Loop Intelligence

Laminar, formerly H2OK Innovations, focuses on inline sensing and AI-driven optimization for liquid manufacturing. Their broader strategy is to make production systems self-aware, using real-time data to tune cleaning cycles, reduce waste, and improve consistency. This patent fits directly into that vision. It strengthens Laminar’s toolkit for understanding what flows inside pipes and how it changes over time, which is essential for scaling food and biotech processes.

The Inventors

Congratulations to the inventors David Lu, Richard M. Mariita, Joseph Sanchez, Jens Hoefflin, and Annie Lu for their contribution to the field.

Lab Grown Technologies highlights meaningful innovations shaping the future of cellular agriculture and tissue engineering.

Join the conversation and share your thoughts on LinkedIn (linkedin.com/company/lab-grown-technologies/).

About the Author — Luke Walton-Jones, MEng (Cantab)

This article is authored by AI and software engineering specialist Luke Walton-Jones. Luke’s work spans machine learning, automation and scalable systems design. A Cambridge-trained engineer, he has led high-impact technical teams, built products from zero to scale and delivered major efficiency gains across global organisations. He’s excited to connect with others exploring the future of AI, ML and modern software engineering.

This post is based on publicly available information. Lab Grown Technologies is not affiliated with the inventors or organizations mentioned.