The future of food depends on more than creating new proteins. They have to work in real kitchens. A synthetic egg white might look perfect on paper, yet fail to foam in a meringue or disappear smoothly into coffee. Today, companies still rely heavily on human tasting panels to judge whether a batch is good enough. This new patent proposes a faster, more objective alternative: letting light, mathematics and machine learning measure quality long before anyone takes a bite.

When light becomes a quality test

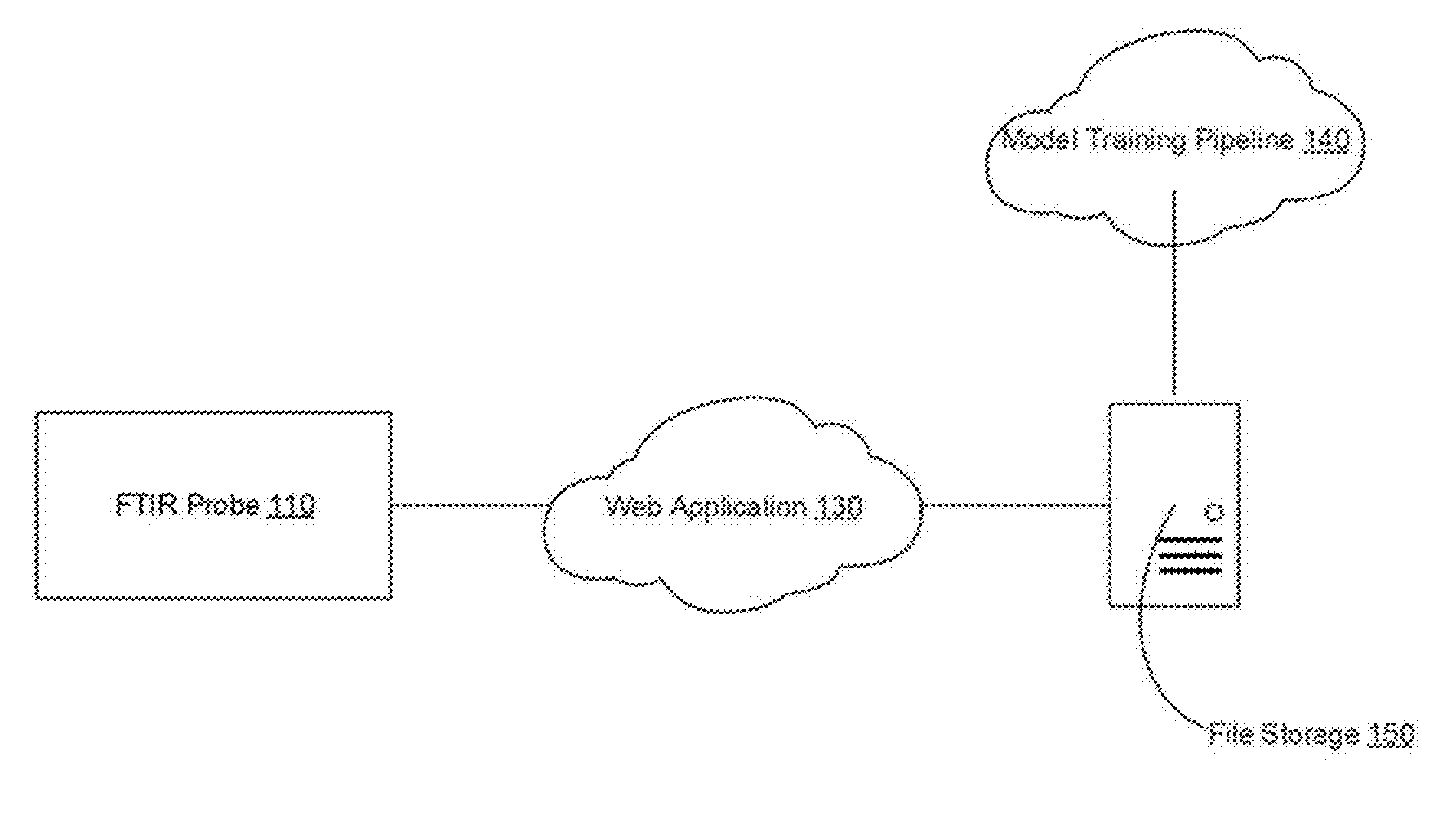

The invention centers on a simple idea. Shine infrared light on a protein ingredient and measure which parts of the light get absorbed. The resulting pattern, or spectrum, acts like a chemical fingerprint. In the system described in the patent (WO2022246284), these fingerprints are collected from protein powders, liquids or mixtures and fed into machine learning models trained to recognize how those fingerprints relate to real-world food performance.

Instead of baking pound cakes or preparing custom lattes for every test, the system predicts whether a protein will be unacceptable, acceptable or great in a specific application. A fermentation operator could see warnings such as “this batch will not perform well in non-dairy milk” while the product is still being purified. The models learn over time and can be trained with or without human sensory data, creating a feedback loop that connects process data directly to functional outcomes.

Image from the EVERY Company’s Patent

A natural extension of The EVERY Company’s strategy

Clara Foods, now operating as The EVERY Company, develops animal-free egg proteins using precision fermentation. Their ingredients end up in foods where texture, foaming, binding and flavor neutrality matter just as much as nutrition. A system that predicts functionality from spectroscopic data aligns with their broader strategy: reduce trial-and-error, streamline production, and provide reliable, scalable replacements for traditional egg proteins.

The people behind the work

Congratulations to the inventors — Zachary Friar, Varsha Gopalakrishnan, Dane Jacobson, Kritika Mahadevan, Ranjan Patnaik and Weixi Zhong — for their contribution to the field.

Lab Grown Technologies highlights meaningful innovations shaping the future of cellular agriculture and tissue engineering.

Join the conversation and share your thoughts on LinkedIn (linkedin.com/company/lab-grown-technologies/).

This article is authored by AI and software engineering specialist Luke Walton-Jones, whose work spans machine learning, automation and scalable systems design. A Cambridge-trained engineer, he has led high-impact technical teams, built products from zero to scale and delivered major efficiency gains across global organisations. He’s excited to connect with others exploring the future of AI, ML and modern software engineering.

This post is based on publicly available information. Lab Grown Technologies is not affiliated with the inventors or organizations mentioned.