Three dimensional cell cultures such as organoids, spheroids, and even future cultured meat are only as good as the oxygen that reaches their core. As tissues get thicker, their centers often become starved of oxygen and nutrients, which limits viability and function. A recently published patent from Canon Inc. explores a very different approach to this classic bottleneck: using electric fields to steer oxygen rich nanobubbles directly into dense cell structures.

Using electric fields to drive nanobubbles into tissues

Instead of just mixing cells into a medium that contains fine bubbles, this invention actively drives those bubbles toward the cells. The patent describes a method where a liquid containing ultrafine bubbles is exposed to a controlled electric field. Because these nanobubbles carry a surface charge, the electric field causes them to migrate through the liquid and into cell layers and 3D tissues.

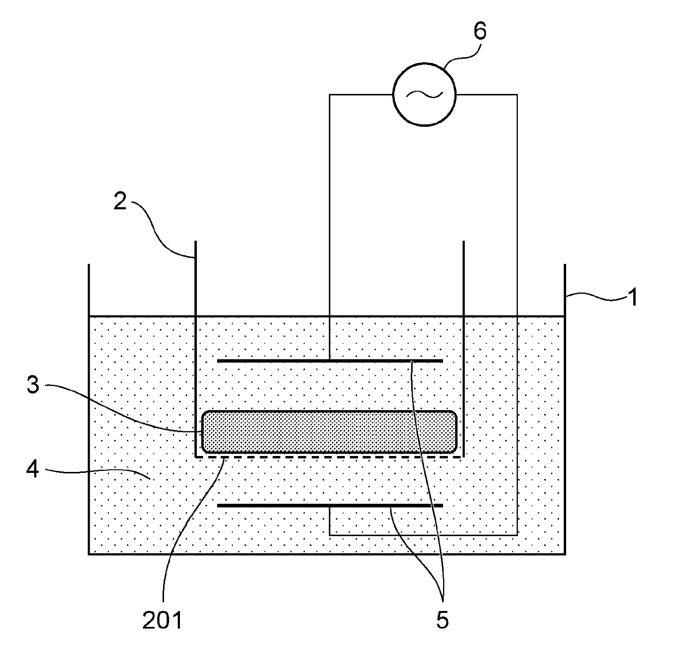

In practical terms, you can picture a culture dish with a multilayer cell sheet or spheroid, surrounded by a medium loaded with tiny oxygen bubbles smaller than 200 nanometers. A pair of electrodes applies a gentle voltage below the level where water starts to electrolyze. The field quietly “pushes” the bubbles into and through the tissue, overcoming the natural electrostatic repulsion between cells and bubbles.

The patent also describes preferred conditions such as bubble concentrations of ten billion bubbles per milliliter or more, and electrode designs that avoid direct contact with the cells. Although framed broadly, this concept is particularly relevant for thick 3D constructs, where conventional diffusion often fails. The work is published as a recent patent application (WO2025205619A1).

Drawing from Canon’s patent displaying the tissue, electrodes and the vessel filled with medium containing microbubbles. (WO2025205619A1)

From imaging to microenvironments at Canon Inc.

Canon Inc. is widely known for imaging and optical technologies, but it has been expanding into healthcare, biomedical tools, and industrial systems. This patent fits a larger pattern: using physical control, not just biochemistry, to fine tune cellular microenvironments. If methods like this can be integrated into bioreactors or culture devices, they could help support thicker tissues, more uniform organoids, or even higher quality cultured meat cuts.

Congratulations to the inventors, Tatsuaki Orihara, Sachiko Yamauchi, and Rui Sekine, for their contribution to the field.

Lab Grown Technologies highlights meaningful innovations shaping the future of cellular agriculture and tissue engineering.

Join the conversation and share your thoughts on LinkedIn.

This post is based on publicly available information. Lab Grown Technologies is not affiliated with the inventors or organizations mentioned.